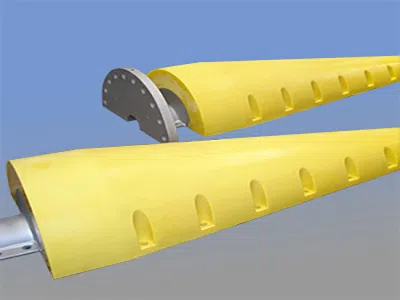

Umbilical vertebrae cable bend restrictors (also called cable bend limiters) are usually used to protect submarine cables or optical fiber cables during installation in submarine or offshore environments to prevent cable damage or performance degradation due to excessive bending. The method of making such a bend limiter usually includes the following steps:

Material selection

• Material resistant to seawater corrosion: Marine cable bend restrictors need to be corrosion-resistant, and high-performance polyurethane (PU) materials are usually selected, which can effectively prevent the erosion of the material by seawater and other environmental factors.

• Both elasticity and rigidity: The material must have a certain elasticity so that it can adapt to certain stresses and deformations in the submarine environment, but at the same time it must also have sufficient rigidity to maintain the shape and direction of the cable.

• High-pressure resistance: In deep-sea environments, bend limiters also need to withstand high water pressure, so the selected materials must have good pressure resistance.

Design the structure of vertebrae bend restrictors

• Appearance design: The shape of the bend restrictor is usually designed to be annular or semi-annular, tightly wrapped around the outside of the cable to ensure that the cable will not be damaged due to excessive bending. A spiral or tubular structure can be used, which can better adapt to the bending needs of the cable.

• Internal structure design: The internal support structure needs to take into account the outer diameter and flexibility of the cable, and at the same time, a reasonable support frame should be designed to maintain the appropriate bending radius of the cable to avoid exceeding the maximum bending limit.

• Multi-layer protection design: Sometimes, the bend restrictor is protected by a multi-layer structure, with the outer layer used for protection and the inner layer used to enhance the bend-limiting effect.

Manufacturing process

• Injection molding: Many submarine cable bend limiters use injection molding technology, which can accurately control the distribution and thickness of the material. This method is suitable for mass production and ensures that the size and shape of each limiter are consistent.

• Hot pressing molding: For bend limiters that require higher strength and high-temperature resistance, hot pressing molding technology may be used to shape the material through heating and high pressure.

• Customized production: Due to the different requirements of each project, you can customize different bend restrictors according to the cable diameter, environmental requirements, etc.

Testing and verification

• Compression test: Pressure test the finished product to simulate the high-pressure environment in the deep sea to ensure that the bend restrictor will not deform or damage during long-term use.

• Corrosion resistance test: Conduct a saltwater corrosion test to verify the stability of the material in seawater and ensure corrosion resistance in long-term use.

• Bend restrictor test: Test the control effect of the bend restrictor on the cable bending to ensure that the bending radius does not exceed the safety limit of the cable.

Installation and application

Umbilical bend restrictors are usually used with bend stiffeners or J-tube centralizers to install the cable in the conduit on the seabed or offshore platform to protect the stability of the cable during laying and long-term operation.

In applications such as offshore wind power and oil platforms, bend limiters can avoid power transmission interruptions or equipment failures caused by excessive bending of cables.

Philson is a manufacturer specializing in the production of marine cable protection accessories. You can directly provide drawings, or we can help you design according to your needs to ensure the provision of high-quality and affordable marine protection solutions.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.