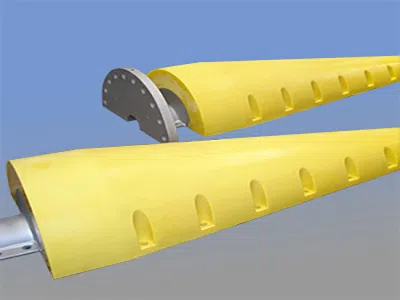

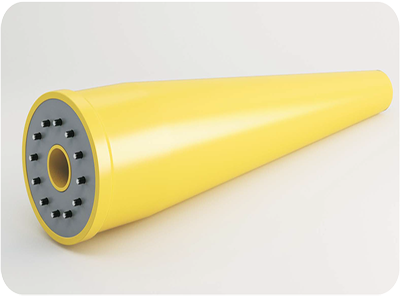

The split flexible protection sleeveis wear-resistant, impact-resistant, and elastic polyurethane material. It is an ideal wear-resistant and impact-resistant protection solution for flexible wire pipe grounding sections such as submarine optical cables, power cables, pipelines, and oil flowlines.

Features of the marine-grade polyurethane cable protection sleeve

• Easy to install: The basic unit length is 1.5 meters, 2.0 meters, or customized. The split tubular half shells are installed in an overlapping and interlocking manner. It can speed up installation and reduce the need for heavy equipment such as barge cranes or auxiliary vessels.

• Wear and impact resistance: Polyurethane has high wear and impact resistance, and is an ideal choice to avoid damage to main cables or pipelines due to seabed movement.

• Lightweight and high strength: The material has a specific gravity of 1.10, which is close to the density of seawater and will not cause additional pressure on pipes and cables. At the same time, the high strength of polyurethane can resist external impact and reduce the risk of damage from falling objects.

• Low maintenance and less downtime: Polyurethane is UV-resistant and has a wide temperature range(-30 °c—80°c and more), with a service life of at least 25 years.

Impact and wear protection systems for multiple applications

- Power cables and fiber optic cables

- Pipeline crossings

- Land and island connections

- River crossings

- Offshore oil and gas fields

- Offshore wind farms

Philson offers custom-designed cable abrasion protectior that can be formulated with additional requirements such as buoyancy, ballast, thermal insulation, or flame retardancy. Easy on-site installation and cost reduction are one of the principles of Philson products.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.