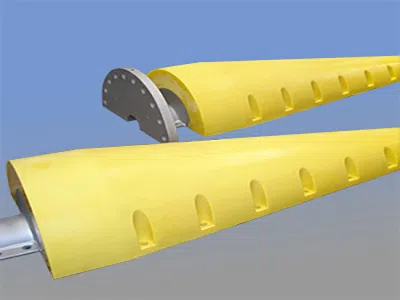

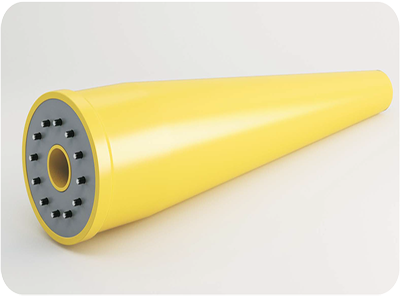

Polyurethane submarine cable interlocking protectors are made of high-quality polyurethane, which is resistant to abrasion, chemicals, impact, and extreme temperatures, protecting submarine cables from physical damage and environmental degradation. This protection solution is ideal for offshore wind farms, oil drilling platforms, and submarine communication systems, improving the service life and performance of critical submarine infrastructure.

Advantages of polyurethane protective tubes

Durability and wear resistance: Polyurethane has strong wear resistance and durability, and its elasticity enables the cable to withstand the friction caused by the constant movement of ocean currents and contact with underwater obstacles.

• Chemical resistance: Polyurethane protective tubes can resist a variety of chemicals such as oil, seawater, and corrosive substances common in deep-sea environments. This chemical resistance helps prevent the degradation of the cable insulation layer and ensures that the performance does not deteriorate for at least 25 years.

• Flexibility and adaptability: Polyurethane consists of two halves of the polyurethane shell fixed by screws or metal bands. It is simple to install, and the length, width, and thickness can be customized according to actual use. Different stages are linked by interlocking, and the length can be freely adjusted.

• Impact and shock absorption: The resilience of polyurethane helps protect the cable from physical shock and vibration caused by nearby equipment, underwater vehicle movement, or fishing activities, and has excellent impact resistance and shock absorption.

• UV and high temperature resistance: Polyurethane tubes can withstand high temperatures and UV exposure of 120-180 degrees, making them ideal for shallow and deep-sea cable systems. It prevents the material from degrading when exposed to sunlight or low temperatures in the deep sea for a long time.

• Reduce costs: Polyurethane submarine cable interlocking protectors are cost-effective due to their diverse and excellent protection performance, reduced maintenance requirements, and replacement cycles. Compared with rigid metal armor, their lightweight design also reduces transportation and deployment costs.

Polyurethane protective tube usage scenarios

Polyurethane protective tubes are commonly used in offshore wind farm umbilicals, oil drilling platforms, natural gas pipelines, and submarine communication networks. These cables usually transmit power, data, or communication signals, usually over long distances and through challenging underwater terrain. The protector is usually installed around the cable during the cable manufacturing or installation stage to ensure that the cable is not mechanically damaged, worn, or corroded after being immersed in water.

Polyurethane submarine cable interlocking protectors provide unparalleled protection for submarine cables in some of the most challenging underwater environments. Polyurethane is durable, chemically resistant, flexible, impact-absorbing, and temperature-adaptable, making it an ideal material to ensure the life and reliability of submarine cables used in offshore applications. Whether in renewable energy projects, offshore oil and gas facilities, or submarine communications, these protectors play a key role in protecting important infrastructure.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.