In subsea construction, especially in offshore oil and gas projects, protecting cables and pipelines from bending damage using bend stiffeners and bend limiters is essential to ensure long-term functionality. While both components help control the bending of subsea cables and pipelines, they work differently and are applied in different ways. Here is a breakdown of the key differences:

Function and purpose

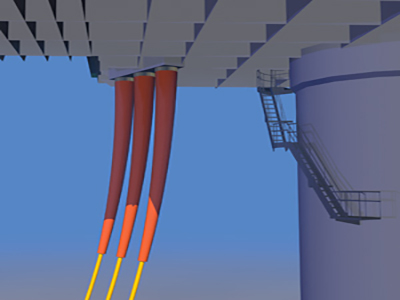

Offshore bend stiffeners are used to prevent excessive bending at critical points, such as where a cable or pipeline leaves a structure or comes into contact with the seabed. The main purpose of a bend stiffener is to provide mechanical reinforcement, adding stiffness to a cable or pipeline and ensuring it remains straight or with minimal bending. This helps reduce the risk of fatigue and failure over time, especially in harsh subsea environments where cables and pipelines are subject to dynamic loads and movement.

Bend limiters:

In contrast, a subsea bend limiter does not directly reinforce a cable or pipeline but rather limits the range of bends. It is designed to control the amount of bending that can occur, preventing sharp angles that could cause damage. Bend limiters are often used to limit bends in transition areas of a cable or pipeline, ensuring that the bend radius remains within a safe operating range. They are typically made up of a series of vertebrae-type elements that are tightly interconnected to prevent the cable from bending too much.

Materials and design

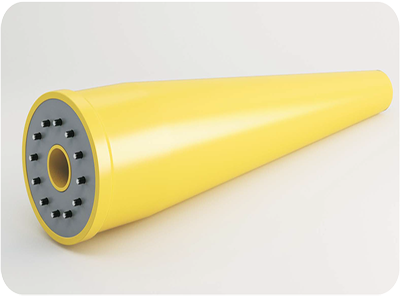

Bend stiffeners:

Bend stiffeners are typically made of rigid materials such as reinforced polyurethane, steel, or composite materials. They have a solid metal reinforcement inside. The design is typically a solid cone that fits over the cable or pipe, providing a high level of stiffness and strength. This ensures the cable or pipe remains straight and resists the bending forces in an offshore environment.

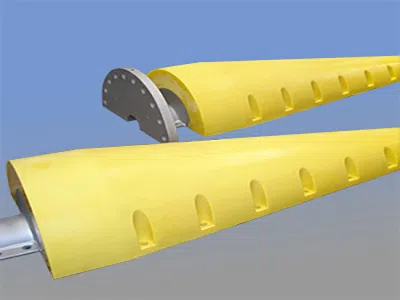

Bend limiters:

Bend limiters are typically made of a flexible material such as polyurethane and have a segmented vertebrae design that is secured using screws. This allows them to bend around the cable or pipe while still limiting excessive bending. The design is typically similar to a series of rings or ferrules that are placed along the length of the cable or pipe at locations where bending is most likely to occur.

Applications and uses

Bend stiffeners:

Bend stiffeners are typically used where cables or pipes leave a structure, such as offshore platforms or subsea connections. These areas are particularly susceptible to high bending moments due to the weight of the cable or pipe and the forces acting on it. Reinforcements are usually placed in a critical location to provide maximum fatigue and failure protection.

Bend restrictors are used in areas where direction changes frequently or the bend radius must be strictly controlled. They are usually applied along the length of the submarine cable or pipeline to ensure that it bends within the allowed range and prevents the cable from being damaged by sharp angles or excessive bending.

Easy to install and maintain

Due to their rigidity, both bend stiffeners and bend restrictors can be designed in an integrated or segmented style without the need for additional installation tools. The more cost-effective polyurethane material does not require maintenance for at least 25 years. They provide a cost-effective solution to prevent sharp bends and protect cables from damage.

Although both bend stiffeners and bend restrictors are essential components in submarine cable and pipeline management, they serve different purposes. Bend stiffeners are designed to increase rigidity and prevent excessive bending, while bend restrictors limit the degree of bending to avoid sharp angles. Understanding the specific needs of submarine installations is key to choosing the right components. If you need any help, please feel free to contact us