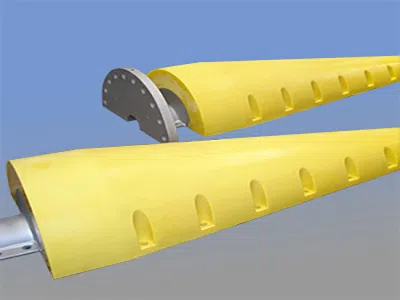

The J-tube seal fixture's split design allows for quick installation. The cost of installing offshore or submarine equipment is high, and it must be done as soon as possible to reduce downtime.

Features

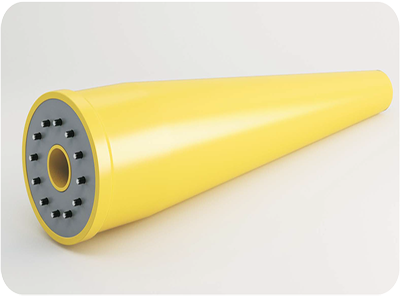

1. It adopts a Haval split modular design, with a polyurethane head in the front. This head perfectly fits the umbilical cable, flexible cable, and pipe, ensuring that they will not bend or wear when entering the J-tube. The metal fixing part at the back is firm.

2. The two-half mold is fixed by nuts or sealing rings to achieve rapid installation of pipes or cables.

3. Anti-corrosion coating and sealing structure: The external coating is used for anti-corrosion and can resist the corrosion of seawater.

Scope of use

Offshore wind farm: Used to protect the cables introduced from the seabed to the wind turbines to ensure their safe operation in complex marine environments.

Submarine cable laying project: Applicable to engineering projects that require cables to be introduced from the seabed to offshore platforms or other structures.

Intertidal and offshore areas: In these areas, the J-tube is fixed to the conduit foundation to protect the cable from the marine environment.

The J-tube centraliser is a cable protection device commonly used in offshore wind farms and submarine cable laying projects. Selecting the right size, hardness, and length of seals is the key to the efficient and normal operation of the equipment and the entire project. It is also important to choose a supplier with rich production experience.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.