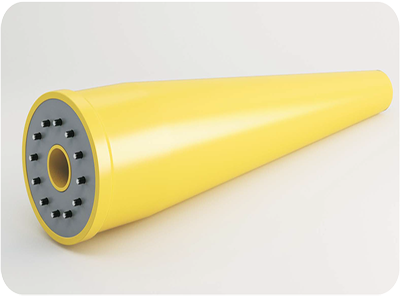

In offshore oil and gas operations, bending stiffeners are primarily used to protect flexible risers, pipelines, cables, or umbilicals from excessive bending stresses, particularly in areas where the pipe or cable is subject to movement or flexing (e.g., at the point of connection to the platform, seabed, or subsea structure). Proper placement of the polyurethane bend stiffener is crucial to ensure that it functions effectively and helps maintain the integrity of the system. Here are four common locations where bend stiffeners can be installed:

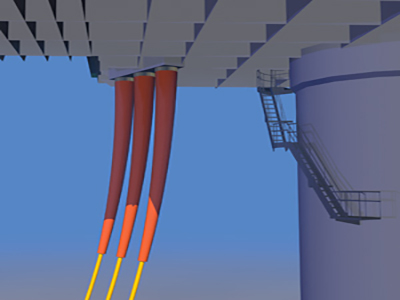

At the top of the riser (platform or floating unit connection)

• Location: Installed at the connection point between the flexible riser or pipeline and the offshore platform, fps (floating production storage and offloading), or other floating production units.

• Purpose: To reduce bending stresses where the riser enters the platform. This point is often subject to dynamic motion (e.g., heave, pitch, and roll), which can create significant bending forces on the riser or cable.

At the bottom of the riser (seabed or subsea equipment connection)

• Location: Installed at the point where the riser or pipeline connects to subsea infrastructure, such as wellheads, manifolds, or subsea trees, at or near the seabed.

• Purpose: To protect the riser from bending at the seabed interface, where forces like currents, tidal movement, and seabed interaction can create additional stresses, potentially damaging the flexible riser or cable.

Mid-length of the flexible riser or cable

• Location: Installed along the length of long flexible risers or cables, particularly in deepwater or ultra-deepwater environments.

• Purpose: To support and reinforce the riser or cable in areas where bending stresses are the highest, typically due to dynamic environmental forces such as wave motion and vessel movements. Mid-length stiffeners help distribute bending loads and reduce fatigue damage.

At connection points to subsea trees and manifolds

• Location: Installed where the flexible riser or cable connects to subsea trees, manifolds, or other subsea equipment.

• Purpose: To minimize bending stress at the critical connection points between the riser and subsea equipment. These locations are subject to mechanical forces and potential abrasion from seabed movement or other equipment, so bend stiffeners provide additional support and protection.

These four locations are commonly selected for installing cable bend stiffeners, as they are typically the points of highest bending stress and where the riser or cable is most vulnerable to damage from environmental and operational forces.

As a cable bend stiffener supplier, Philson is committed to providing innovative and custom marine cable protection system accessories to meet the different needs of customers. Such as bend restrictors, buoyancy blocks, j-tube centralizers, and other cable protection solutions. You can provide drawings and we will help you produce, or you can put forward your needs and Philson will help you. You don't have to worry about design, production, testing and after-sales.