Polyurethane subsea driverless bend stiffener for offshore platform installations represents a groundbreaking innovation in subsea engineering, designed to protect flexible pipelines, umbilicals, and cables from excessive bending stresses during deployment and operation in harsh marine environments. By eliminating the need for human intervention in deepwater or high-risk conditions, this autonomous technology ensures safer, more reliable, and cost-effective offshore energy projects.

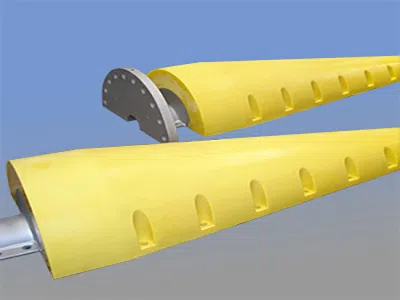

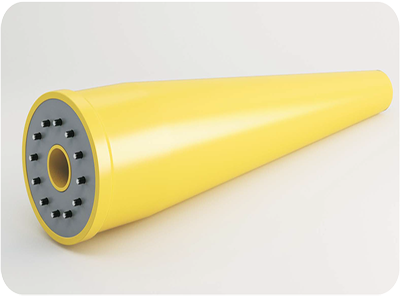

Polyurethane bend stiffener core functionality and design

The subsea driverless bend stiffener for offshore platforms operates by maintaining optimal bend radii in dynamic subsea structures, preventing fatigue failure and prolonging asset lifespans. Unlike traditional bend stiffeners requiring diver-assisted installation, this system integrates robotic manipulators, real-time strain sensors, and AI-driven control algorithms to autonomously adjust clamping forces and alignment. Constructed from corrosion-resistant compliant polyurethane, the stiffener withstands extreme pressures, saltwater corrosion, and temperatures ranging from -20°C to 120°C, making it ideal for deepwater oil and gas fields or offshore wind farms.

Cable bend stiffener for subsea operational advantages

Risk mitigation: Removing divers from subsea operations reduces exposure to underwater hazards, such as entanglement or equipment malfunctions, while ensuring compliance with stringent safety regulations.

Precision engineering: Machine learning algorithms analyze pipeline dynamics in real-time, enabling micro-adjustments to prevent overbending or buckling during installation or storm-induced movements.

Cost efficiency: Automated systems minimize vessel downtime and labor costs, accelerating project timelines by up to 40% in depths exceeding 1,000 meters.

Environmental adaptability: The stiffener’s anti-fouling coatings and modular design ensure resilience against marine growth, strong currents, and abrasive seabed conditions.

Applications in offshore energy

Oil and gas: Critical for flexible risers connecting floating production units to subsea wells, the driverless stiffener safeguards against bending stresses caused by wave motion or platform drift.

Renewable energy: In offshore wind farms, it secures dynamic export cables linking turbines to substations, maintaining electrical integrity despite tidal forces.

Decommissioning: Supports safe retrieval of aging infrastructure by stabilizing pipelines during cutting and lifting operations.

Integration with digital technologies

Modern subsea driverless bend stiffeners are paired with ROV (Remotely Operated Vehicle) interfaces and IoT-enabled monitoring systems, allowing engineers to oversee operations from onshore control centers. Predictive maintenance algorithms leverage historical data to forecast wear, while digital twins simulate scenarios to optimize performance in real-time.

Future trends of bend stiffeners for offshore platform

As offshore projects push into deeper, more remote locations, demand for autonomous solutions will surge. Innovations like 3D-printed stiffeners for rapid customization and AUV (Autonomous Underwater Vehicle)-)-assisted deployments are poised to redefine subsea operations, aligning with global goals for safer, greener energy production.

The subsea driverless bend stiffener for offshore platformembodies the shift toward intelligent, human-free subsea engineering. By merging robust mechanical design with cutting-edge automation, it addresses the dual challenges of operational safety and technical precision, positioning itself as a cornerstone of sustainable offshore energy development. As industries embrace digitalization and environmental stewardship, this technology will play a pivotal role in unlocking the potential of deepwater resources while protecting marine ecosystems.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.