The subsea umbilical bend stiffener is a specially designed component designed to protect the subsea umbilical cable from excessive bending at the connection point with rigid structures such as wellheads and production platforms. It maintains the minimum bending radius of the cable through a tapered reinforcement design, thereby effectively preventing damage caused by excessive bending. The stiffener is usually made of high-grade polyurethane material with excellent flexibility, fatigue resistance, and durability in harsh subsea environments.

Key features of umbilical bend stiffener:

Function: Limit the bending stress at the end of the umbilical cable by providing additional rigidity to prevent cable damage caused by excessive bending during installation or dynamic movement in the subsea environment.

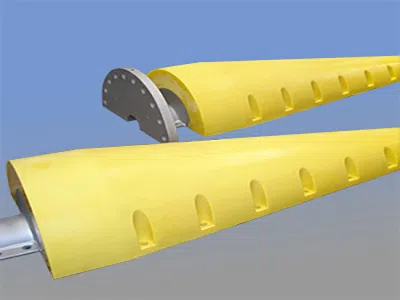

Design: Usually conical, the cylindrical hole design facilitates the umbilical cable to slide through, gradually increasing the rigidity of the connection point to ensure that the cable is well supported.

Material: Mainly made of polyurethane material, it can withstand harsh subsea conditions due to its excellent flexibility, fatigue resistance, and excellent durability. Polyurethane can ensure long-term use under normal conditions, usually without replacement within 25 years, with the advantages of cost-effectiveness and maintenance time-saving.

Applications: Widely used in subsea facilities, including wellhead connections, riser systems, and manifold joints.

Dynamic and static applications: Umbilical bend stiffeners can be designed for static applications (relatively constant bending loads) or dynamic applications (waves and currents cause large fluctuations in bending loads) as needed.

Applications of umbilical bend stiffeners:

Offshore oil and gas platforms: Usually installed at the connection between the umbilical cable and the riser system on the subsea equipment or platform to ensure that the umbilical cable remains fixed and prevents cable failure due to excessive bending.

Subsea Christmas trees and manifolds: Used for the connection between the umbilical cable and subsea equipment (such as Christmas trees and manifolds) to ensure that the cable is not damaged by excessive movement or bending during the transmission of fluids, chemicals, or electricity.

Subsea riser system: The umbilical cable is routed from the subsea riser along the riser system to the ground platform. The bend stiffener helps maintain the integrity of the cable as it passes through the riser and prevents it from deforming during installation, operation, or repositioning.

Deepwater and ultra-deepwater applications: In high-pressure environments such as deepwater and ultra-deepwater oil fields, umbilical cord bend stiffeners can prevent cables from excessive bending or entanglement under high water pressure, protecting the safety of umbilical cables.

Subsea wind farms: In subsea wind turbine applications, umbilical bend stiffeners can protect cables that provide power, data, and control functions to subsea turbines, ensuring long-term reliable operation of cables.

Summary:

Subsea cable protection systems play a vital role in ensuring the stability and safety of umbilicals, flowlines, cables,s, and flexible pipes, and can effectively prevent fatigue, damage or failure of cables caused by bending. Whether static or dynamic applications, they can cope with extreme subsea environments and ensure long-term reliable operation under harsh conditions such as high pressure, deep water, and waves. This makes umbilical bend stiffeners an indispensable key component in offshore oil and gas, deepwater applications, and subsea wind power.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.