Polyurethane split cables bend stiffeners in dynamic subsea are revolutionizing the protection of subsea cables, umbilicals, and flexible pipes by combining advanced material science with innovative design. These components serve as critical safeguards in offshore energy, telecommunications, and marine infrastructure, mitigating bending stresses at vulnerable transition points where rigid structures meet dynamic cables. Engineered to withstand harsh marine conditions, polyurethane split cable bend stiffeners ensure operational longevity while simplifying installation and maintenance.

Design and material advantages

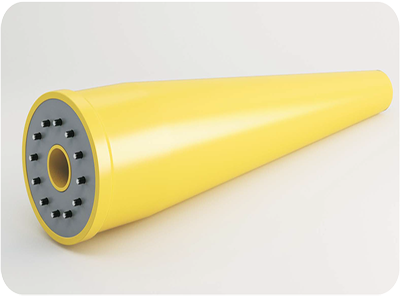

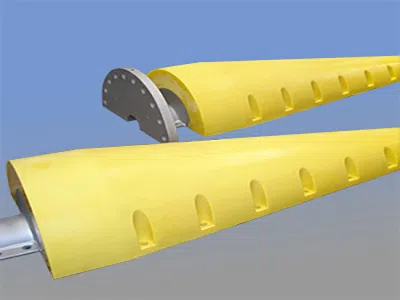

Cable bend stiffeners leverage the unique properties of polyurethane—a material renowned for its elasticity, abrasion resistance, and durability. Unlike traditional one-piece stiffeners, the split design allows for retrofitting onto existing cables without disassembly, significantly reducing downtime during upgrades or repairs. The tapered, conical shape of these stiffeners ensures a gradual stiffness transition, distributing mechanical loads caused by waves, currents, or vessel movements.

Advanced manufacturing techniques, including injection molding and CNC machining, enable precise customization of wall thickness, taper angles, and diameter. This adaptability ensures compatibility with cables ranging from fiber-optic lines to high-voltage power umbilicals. Furthermore, polyurethane’s resistance to saltwater corrosion, UV radiation, and extreme temperatures (-40°C to 80°C) makes it ideal for subsea and coastal applications.

Key applications of cable bend protection system

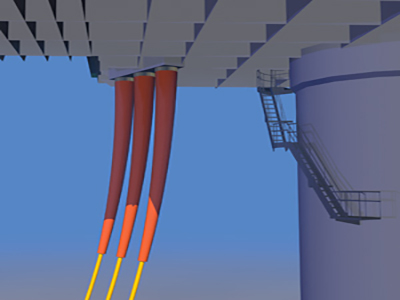

• Offshore wind farms: Polyurethane split cables bend stiffeners to protect dynamic cables linking turbines to floating substations, preventing fatigue failures caused by tidal forces.

• Oil & gas systems: They shield umbilicals and risers at subsea wellheads, where cyclic loading risks metal fatigue and leaks.

• Telecommunications: Subsea fiber-optic cables rely on these stiffeners at seabed entry points to maintain signal integrity under constant motion.

• Marine research: Remotely operated vehicles (ROVs) and sensors are them to ensure uninterrupted data transmission in deep-sea exploration.

Benefits of the split design

• Ease of Installation: The split structure eliminates the need for cable disassembly, cutting deployment time by up to 50%.

• Cost efficiency: Reduces operational disruptions and maintenance costs associated with traditional solid stiffeners.

• Enhanced safety: Prevents over-bending and abrasion, minimizing risks of cable breaks or environmental hazards.

• Customization: Adaptable to specific load profiles, depths, and environmental conditions, supporting bespoke engineering solutions.

Innovations in subsea protection

Modern polyurethane split cables bend stiffeners integrate smart monitoring features, such as embedded strain sensors, to provide real-time data on stress distribution. This innovation enables predictive maintenance, further extending asset lifespans. Manufacturers also prioritize sustainability by developing recyclable polyurethane blends, aligning with global initiatives to reduce marine pollution.

Choosing the right solution

Selecting optimal polyurethane bend stiffeners requires evaluating factors like water depth, wave dynamics, cable diameter, and temperature ranges. Collaboration with experienced manufacturers ensures designs meet ISO 13628-5 and API 17J standards. For ultra-deepwater projects, stiffeners may incorporate anti-hydrolysis additives, while Arctic applications demand low-temperature flexibility.

Partnering for success

As offshore energy and data networks expand, split bend stiffeners are indispensable for resilient subsea infrastructure. Their blend of flexibility, durability, and adaptability addresses the evolving challenges of marine engineering.

Consult Philson's expert team for tailored solutions that enhance your project’s reliability. With decades of experience in polyurethane technologies and subsea innovation, Philson delivers precision-engineered bend stiffeners optimized for performance in the harshest environments.