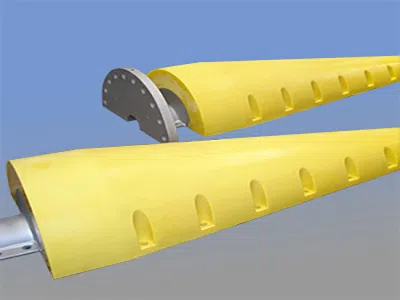

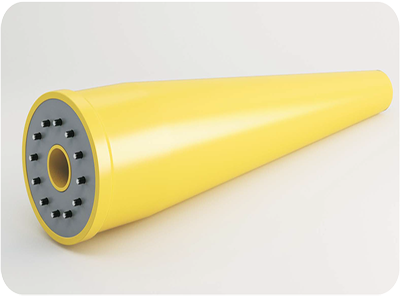

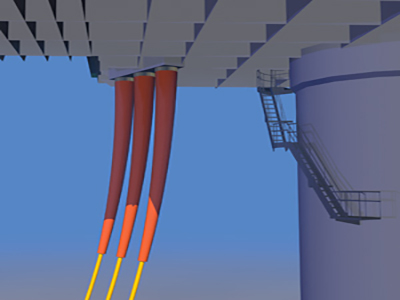

As a high-performance industrial component, polyurethane bending limiter is widely used in oil pipelines, cable protection, mechanical connections, and other fields. Its core function is to limit the excessive bending of the material when it is stressed, thereby improving the safety and durability of the system. Polyurethane materials are ideal for manufacturing such components due to their excellent wear resistance, elasticity, and chemical corrosion resistance. This article will explore the casting methods and advantages of polyurethane bend limiters in depth.

Urethane casting, also known as polyurethane molding and casting molding, is a commonly used polyurethane material molding method. This method pours the polyurethane raw material into the mold in liquid form, fills the gap of the mold to create the required shape and size, and solidifies after a certain period of reaction to obtain the desired shape of the product.

The steps of the polyurethane casting process usually include: mold manufacturing, material mixing, vacuum degassing, injection, and curing.

The specific steps are as follows

• Design the mold: Make the mold according to the CAD design file of the required part. The mold has high precision and durability and can be reused many times.

• Mixing polyurethane stock solution: According to the requirements of the desired end product, polyurethane materials are mixed in specific proportions to ensure that the cured material has the required hardness, elasticity, and durability. During the mixing process, colors and other additives are usually added to meet specific needs.

• Demolding design: Due to the strong adhesion of polyurethane, the mold surface needs to be coated with a release agent (such as silicone oil or fluorocarbon coating), and a reasonable draft angle should be designed.

• Pouring liquid: The mixed polyurethane material is vacuum degassed to remove bubbles. After vacuum degassed, the polyurethane material is injected into the mold that has been preheated at a certain temperature in advance. The injection process usually uses a dedicated injection machine to control the flow and filling speed of the material.

• Curing of polyurethane liquid: As the polyurethane material cures in the mold, a part with the desired structure and performance is finally formed. The curing of polyurethane requires precise control of temperature (80-120°C) and time (5-30 minutes) to ensure that the cross-linking reaction is fully completed. Insufficient curing will cause the material strength to decrease, while excessive heating may cause thermal degradation. During the curing process, the chemical reaction of the polyurethane material will give it high strength and wear resistance.

Post-processing and quality inspection: After the curing is complete, the polyurethane parts can be removed from the mold, and the overflow can be removed by mechanical cutting or laser processing. Hardness test (Shore A/D), tensile strength test, and dynamic fatigue test are carried out later to ensure that the product meets industrial standards.

Polyurethane casting process has the following advantages:

• Rapid manufacturing: Compared with traditional cutting and processing methods, the polyurethane casting process is a relatively efficient and fast manufacturing method. It can produce complex parts and models in a short time, saving the manufacturing cycle.

• Low cost: Compared with other molding methods, such as injection molding or metal casting, polyurethane casting is less expensive. The manufacturing cost of the mold is relatively low, and the price of the material is relatively cheap.

• High precision: Polyurethane materials have high fluidity when liquid and can fully fill the fine details of the mold. The polyurethane casting process can produce high-precision and detailed parts and models, which can fully meet the needs of various applications.

The casting method of polyurethane bending restrictors can achieve mass production, reduce costs, and the product hardness and flexibility are irreversible, and it is environmentally friendly. If you need further information about the processing details of polyurethane bend limiters, please contact us for detailed consultation.