The split polyurethane J-tube centralizer is a key component for the rapid installation, guidance, and protection of cable conduits in J-tubes of marine engineering. It ensures that the cable remains centered during installation, reduces friction and damage to the pipe wall, and thus extends the service life of the cable.

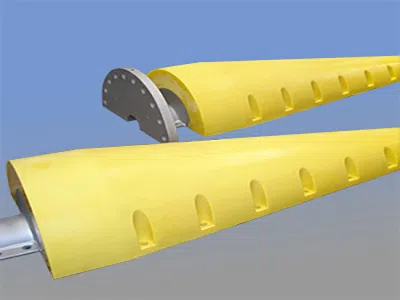

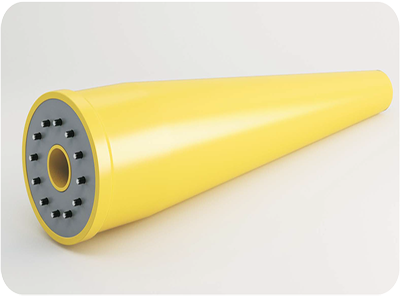

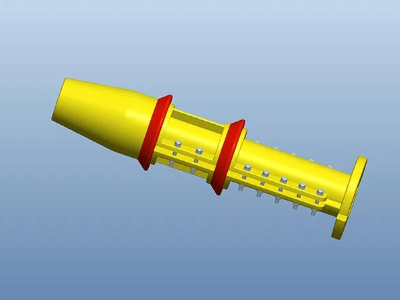

Structure of the split polyurethane J-tube centralizer

The upper part is made of polyurethane, and the conical design better fits the cable conduit to ensure centering. The elastic polyurethane can avoid damage to the cable during stretching and extend the service life.

The lower part is made of metal, with a split design, which can better fit and fix the cable or pipe, and needs to be fixed with screws or other parts.

The split design enables rapid installation and reduces downtime and cost.

The role of the split polyurethane J-tube centralizer

The split polyurethane J-tube centralizer is specially designed for offshore cable threading scenarios. The main functions include:

Precise positioning: ensure that the cable remains centered in the J-tube (curved conduit) to avoid friction or extrusion with the pipe wall.

Mechanical protection: Reduce vibration damage to cables in dynamic marine environments (such as tides and hull shaking).

Extend life: Reduce the risk of insulation wear and improve system reliability by evenly dispersing cable stress.

Simplify maintenance: The split design facilitates later inspection or replacement, reducing operation and maintenance costs.

Core advantages of polyurethane materials

Polyurethane (PU) is the preferred material for this type of centralizer, and its characteristics perfectly match the needs of marine engineering:

Excellent wear resistance: The wear resistance coefficient of polyurethane is 5-8 times that of rubber, and it can withstand long-term friction of cables.

Corrosion and aging resistance: It has strong tolerance to seawater, ultraviolet rays, and oil pollution, and its life can reach more than 20 years.

High elastic buffer: The elastic modulus is moderate, which can absorb impact energy and maintain structural stability.

Lightweight design: The density is lower than metal, which reduces the installation load and is suitable for deepwater operations.

Environmentally friendly and non-toxic: It meets the IMO (International Maritime Organization) marine environmental protection standards.

Installation method

The installation steps of the split polyurethane J-tube centralizer are as follows:

Preparation: Ensure that the cable and the inner wall of the J-tube are clean and free of impurities.

Assembling the centralizer: Assemble the parts of the centralizer around the cable to ensure that the components are tightly connected.

Fix the centralizer: Use special fasteners (such as stainless steel bolts or straps) to fix the centralizer to the cable to ensure that it does not move during installation.

Cable laying: Slowly pull the cable with the centralizer installed into the J-tube to ensure that the centralizer passes through the curved part of the pipeline smoothly to avoid jamming.

Inspection and adjustment: After the cable is laid, check the position and fixation of the centralizer to ensure that the cable is centered in the J-tube and there is no abnormality.

The split polyurethane J-tube centralizer can effectively ensure the correct positioning of the cable in the J-tube, reduce mechanical damage, and improve the reliability and service life of the offshore engineering cable system. Filson can provide center clamps of various sizes and technical requirements you need. If you need, please contact us for relevant details.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.