Umbilical vertebrae bend restrictors are critical components to prevent overbending and subsea cable damage. These cables are often used in offshore oil and gas operations, providing essential services such as power, data transmission, and fluid transfer between surface and subsea structures. Well-designed cable bend restrictors help maintain the integrity of these cables, protecting them from strain, fatigue, and potential failure caused by excessive bending in the harsh underwater environment.

Key function: Prevent bending

The primary purpose of an umbilical bend restrictor is to limit the bend radius of subsea cables, preventing them from exceeding their designed curvature. Excessive bending can cause severe internal damage such as conductor failure, signal loss, or leakage. Bend restrictors ensure that the cable maintains its optimal configuration when subjected to motion or environmental forces such as ocean currents or equipment handling by creating a controlled, progressive bend.

These products are particularly useful in subsea installations where the cable must traverse complex, rugged subsea terrain or around sharp corners. By managing the bend profile, umbilical bend restrictors extend the life of subsea cables and reduce the need for costly repairs or replacements.

Design and materials: Durability in harsh subsea environments

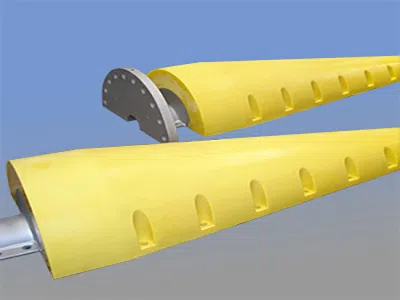

Vertebrae bend restrictors are made from high-strength materials that are resistant to corrosion, abrasion, and harsh conditions found in deep-sea environments. Materials such as high-density polyethylene (hdpe), polymer, or polyurethane are widely used for their durability and weather resistance. These materials help bend restrictors withstand the extreme pressures and temperatures found in the deep sea.

Bend restrictor designs typically consist of a series of interlocking “vertebrae” that form a flexible yet strong structure. This design is easy to install and allows for optimal flexibility while maintaining the necessary strength to prevent damaging bends. The vertebrae design is particularly effective in distributing bending forces, thereby ensuring that the subsea umbilical cable maintains its integrity for a long time.

Easy installation: Reduced downtime and costs

One of the main advantages of using subsea bend restrictors is their ease of installation. Designed to be simple to use, these products can be installed along the length of the cable before or during deployment. This reduces operational downtime and simplifies the process of protecting subsea cables.

Vertebral bend limiters are guaranteed not to require replacement for at least 25 years, avoiding costly modifications or repairs. Thus, they help to save overall costs during installation and over the service life.

Applications: Offshore oil, gas and renewable energy

Umbilical bend restrictors are widely used in subsea applications such as offshore oil and gas exploration and renewable energy projects such as subsea wind farms, playing a vital role in the transmission of power, fluids, and communication signals through cables. It effectively protects cable safety in offshore oil and gas operations such as deepwater drilling, subsea well intervention, and pipeline installation. In the renewable energy sector, it protects subsea cables connecting floating wind turbines to the grid, minimizing the risk of damage during installation and operation, thereby ensuring operational efficiency and safety.

Whether you are engaged in offshore drilling operations or subsea renewable energy projects, investing in cable bend limiters is key to maintaining cable integrity and minimizing operational risks.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.