Submarine cable umbilical bend restrictors are critical components in offshore and subsea environments to prevent cables and umbilicals from excessive bending or damage, ensuring their integrity and durability under harsh conditions such as high pressure, dynamic movement and mechanical stress. By preventing sharp bends, it improves the performance and service life of the cable in the subsea environment.

• Principle of operation

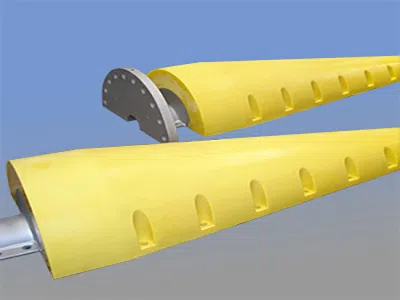

The core function of the cable umbilical bend limiter is to limit the minimum bending radius of the cable and umbilical to prevent damage caused by excessive bending stress. It wraps the cable through a flexible or rigid structure to provide a support framework to ensure smooth movement of the cable along a gradually curved path. In a dynamic seabed environment, the bend limiter acts as a buffer to absorb and disperse the impact of water currents, waves and mechanical forces, protecting the conductor and insulation of the cable from damage.

• Materials used

Polyurethane is a popular choice for subsea bend restrictors due to its superior abrasion resistance, flexibility, and ability to endure harsh marine conditions. It is resistant to corrosion, UV radiation, and the challenging temperatures found in subsea environments, making it ideal for long-term use in deepwater applications.

• Installation method

When installing polyurethane vertebrae bend restrictor, it is wrapped around the cable in sections or as a continuous unit, the length can be adjusted by itself, and fixed with mechanical accessories or bolted joints to ensure that it is stable and does not move. The limiter should be installed at the key points where the cable is subjected to the greatest pressure, such as cable entry/exit, J-tube or easy bending area to ensure the best protection effect.

• Usage conditions

High-quality submarine cable bend limiter needs to withstand high pressures of more than 300 bar in deepwater applications and maintain flexibility and strength at low temperatures of -4°c to 4°c. It also needs to adapt to dynamic movements caused by tides, waves or ship operations to avoid fatigue damage. In addition, the bend limiter is made of corrosion-resistant polyurethane material to resist seawater erosion and chemical degradation in environments such as oil fields or underwater mining.

• Usage industry

Bend restrictors are widely used in multiple industries, including oil and gas, offshore wind power, seabed mining, marine research and telecommunications. In the oil and gas field, it protects cables that transmit power and control signals; in offshore wind power, it ensures safe power transmission; in deep-sea mining, it protects power supply and control cables; in marine research, it ensures communication and power transmission; in the telecommunications industry, it protects submarine optical cables and ensures the integrity of long-distance data transmission.

Contact us today for your submarine cable protection system needs. If you are looking for a high-quality solution, Philson offers reliable and durable custom designs using premium materials to ensure long-term, efficient operation in harsh subsea environments. Contact us to learn more and improve the safety and reliability of your subsea operations.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.