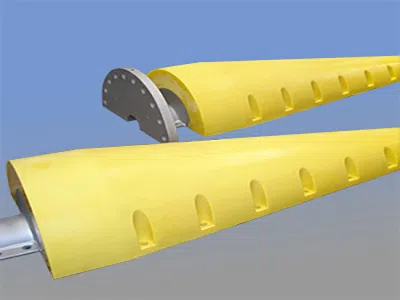

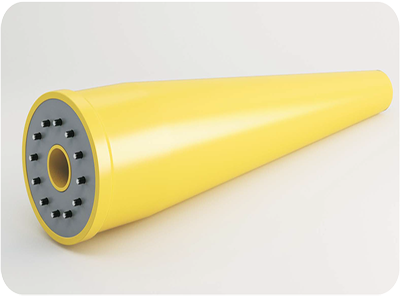

Designed to safeguard critical subsea infrastructure, Philson bespoke boltless vertebrae cable bend restrictors deliver unparalleled protection against excessive bending for oil and gas umbilicals, subsea cables, flowlines, flexible risers and jumpers, and offshore wind farm installations. Engineered with precision and durability in mind, these restrictors combine cutting-edge design with marine polyurethane material to ensure long-term performance in harsh underwater environments.

Key features & benefits

• Durable marine polyurethane construction

Crafted from high-grade marine polyurethane, these bend restrictors resist corrosion, abrasion, and chemical degradation, making them ideal for subsea applications. The material’s flexibility ensures optimal grip on cables while maintaining structural integrity under extreme pressures.

• oltless interlocking design

The innovative boltless interlocking mechanism eliminates the need for complex hardware, reducing installation time and minimizing potential failure points. This design allows for rapid installation time, even in challenging subsea conditions, and ensures a secure fit around cables and umbilicals.

• API 17l 1&2 certified compliance

Fully compliant with API 17l 1&2 certification standards, our restrictors meet the stringent requirements for subsea reliability, ensuring compatibility with global oil and gas projects and offshore renewable energy systems.

• ROV-friendly & interchangeable parts

Designed for effortless maintenance, these restrictors can be easily removed with ROV (remotely operated vehicle) technology, reducing downtime during repairs or adjustments. Every part is interchangeable, streamlining replacements and keeping installation a simple, cost-effective process.

• Modular flexibility for diverse applications

The segmented vertebrae structure allows customization to fit varying cable diameters and bending radii. Whether deployed at the seabed, platform or along flexible risers, the modular design adapts seamlessly to protect infrastructure in dynamic subsea environments.

Applications across industries

Our bend restrictors are trusted in high-stakes industries:

• Oil & gas: Shield umbilicals and flowlines from bending stress near wellheads or manifolds.

• Offshore wind farms: Protect inter-array cables and dynamic jumpers from tidal forces.

• Subsea power grids: Secure high-voltage cables in renewable energy projects.

Why choose Philson bend restrictors?

• Prevent excessive bending: The articulated vertebrae structure distributes mechanical stress evenly, preventing sharp bends that could damage cables.

• Cost-effective maintenance: Interchangeable components and ROV compatibility slash operational costs.

• Future-proof design: Compatible with existing subsea setups and adaptable to evolving project needs.

Certifications & reliability

Beyond API 17l certification, our restrictors undergo rigorous testing for UV resistance, hydrostatic pressure, and fatigue endurance. The marine polyurethane formulation ensures compliance with environmental regulations, making them suitable for sensitive ecosystems.

For subsea projects demanding reliability, efficiency, and durability, our bespoke boltless vertebrae cable bend restrictors offer a proven solution. By integrating boltless interlocking technology, ROV-friendly design, and certified materials, we empower offshore operators to protect their investments while minimizing downtime.

Whether you’re securing cables in deep-sea oil fields or offshore wind farms, trust our restrictors to deliver unmatched performance—engineered for the challenges beneath the waves.

Contact us today to customize a solution tailored to your subsea needs!

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.