Marine-grade polyurethane sheets are essential materials in subsea construction, with anti-collision, impact resistance, shock absorption, durability, flexibility, and resistance to extreme environmental conditions. Customized polyurethane sheets are tailored to meet the needs of subsea applications, making them a key solution for a variety of offshore and underwater construction equipment. These materials are increasingly favored for their high performance, providing reliable protection and extending the service life of subsea structures.

The main features of customized polyurethane sheets

• High wear resistance: Marine-grade polyurethane flat sheets are known for their excellent wear resistance. In harsh subsea environments, equipment is often subject to wear and tear from sand, rocks, and other debris. The wear resistance of polyurethane makes it an ideal material for protecting and enhancing subsea construction equipment.

• Impact resistance and vibration reduction: Anti-collision polyurethane sheets are known for their excellent energy absorption ability, which can effectively dissipate the forces generated by shocks, vibrations and impacts. This feature significantly reduces the risk of damage to sensitive subsea equipment such as pumps, valves, cables, and structural components.

• High resilience: This means that flexible polyurethane sheets can absorb and cushion repeated or sudden shocks, protecting machines from mechanical wear. This flexibility and strength also enable them to maintain performance over long periods of time despite constant exposure to underwater pressure, currents, and physical stress.

• Excellent corrosion resistance: Corrosion is one of the most significant challenges in subsea construction. Polyurethanes offer excellent resistance to seawater, chemicals, and other corrosive substances, ensuring that equipment remains functional and durable even when exposed to underwater environments for extended periods of time.

• High load-bearing capacity: Subsea equipment is subjected to tremendous pressure, especially in deep-sea environments. Custom polyurethane boards are designed to withstand high loads without compromising flexibility, making them ideal for structural applications where strength and stability are critical.

• Chemical and UV resistance: Polyurethane boards maintain their integrity even when exposed to a wide range of chemicals common in subsea environments, including oils and hydrocarbons. Additionally, they are resistant to UV degradation, ensuring long-lasting performance even when exposed to sunlight during installation and maintenance.

• Custom sizes and thicknesses: One of the standout benefits of PU gasket sheets is the ability to tailor the material to meet specific project needs. Whether a thinner sheet is required for a flexible application or a thicker sheet is required for high-pressure protection, custom polyurethane sheets can be manufactured to meet the exact dimensions and requirements of any subsea construction project.

Applications in subsea construction equipment

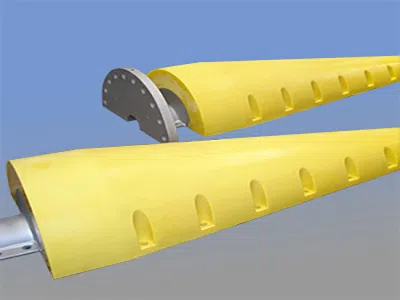

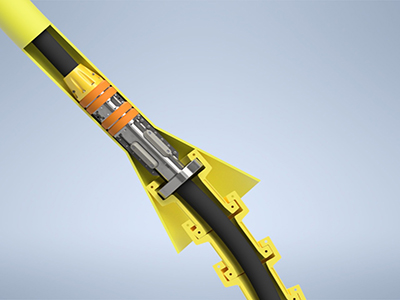

• Pipeline protection: Polyurethane sheets are often used to protect subsea pipelines from external damage such as abrasion, impact, and exposure to chemicals. They act as a protective barrier to ensure that pipelines maintain their structural integrity during installation and operation.

• Shock absorbers and cushions: The excellent shock absorption properties of polyurethane make it an ideal material for subsea equipment that is subject to high impact or vibration. PU sheets are used to cushion and absorb shock in structural components such as valves, pumps, and machinery used in deepwater environments.

• Subsea construction pads: Urethane sheets can also be used as pads or liners to protect underwater equipment from rough or uneven seabeds during installation. These pads can be customized to fit the contours of the equipment and the seabed, preventing damage caused by physical contact.

• Subsea storage and containment: Custom polyurethane sheets are used to manufacture containers and housings that protect subsea equipment such as tools, sensors, and storage units. These containers ensure that sensitive equipment remains safe and functioning properly in harsh subsea environments.

Philson is a manufacturer that has focused on marine protection systems for many years, providing a full range of design, production, forecasting, and after-sales services. Put forward your needs and we will give you a solution!

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.