J-tube centralizers are designed for offshore platforms and wind turbine structures to guide and protect submarine cables when they are laid through J-tubes. Their core function is to ensure that the cable is accurately centered and aligned in the J-tube, effectively reducing the risk of mechanical damage, improving the reliability of the cable system, and extending its service life.

Construction and design

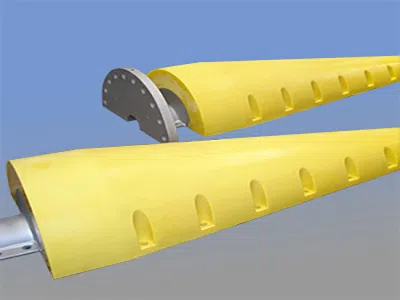

Centralizer body: A cylindrical or segmented metal frame that surrounds the cable, split into two halves to facilitate installation.

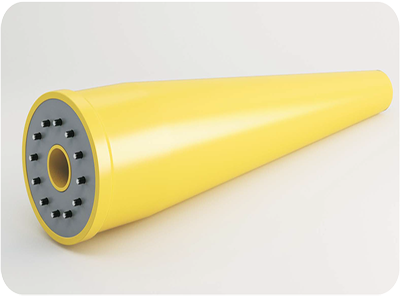

Polyurethane head: Minimizes friction between the cable and the J-tube.

Locking mechanism: Bolts and polyurethane ferrules secure the centralizer in place.

Available in split or modular designs, they can be easily installed around the cable. Available to accommodate different J-tube diameters (e.g., 200-800 mm) and cable configurations.

Material properties

The head of the J-tube centralizer is manufactured from high-performance polyurethane, selected for its excellent resilience, wear resistance, and superior mechanical properties. The polyurethane section prevents damage to internal structures such as cable flowlines or conduits during pulling, providing high load-bearing capacity and long-term durability in harsh marine environments. It is resistant to seawater corrosion, oil, and chemicals, ensuring that the centralizer maintains integrity and functionality throughout the service life of the subsea system.

Functions and benefits

The primary function of the J-tube centralizer is to center and stabilize the cable as it passes through the J-tube, reducing the risk of damage due to wear, vibration, and impact. They also enable smoother cable installation, reduce pulling forces, and minimize stress on the cable jacket. By preventing contact with the J-tube wall, the centralizer protects the cable's insulation and improves the safety and performance of the entire system.

Use scenarios

J-tube centralizers are widely used in subsea energy applications, including offshore wind farms, oil and gas platforms, and inter-array or export cable systems. They are particularly important in projects that require the laying of high-voltage cables through complex or curved pipelines. Whether during initial cable laying or maintenance operations, J-tube centralizers are key components to ensure safe and efficient cable management in offshore environments.

J-tube centraliser devices are important for protecting submarine cables from mechanical wear and achieving fast installation. Filson is well aware that size fit, reasonable price, convenient installation, and low-cost maintenance are factors that must be considered, and has always taken these as its own production and customization principles. If you want to learn more, please feel free to contact us

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.