Polyurethane board is a material that is a good replacement for rubber and plastic. It is known for its high wear resistance, high corrosion resistance, and high resilience, as well as lower friction and less material adhesion. Compared to plastics, urethanes offer superior impact resistance, while offering excellent wear properties and elastic memory.

Polyurethane boards are versatile materials widely used in industrial and marine applications due to their excellent mechanical and chemical properties. Here's a detailed overview of their characteristics, marine suitability, and parameter information:

Characteristics of polyurethane boards

• Mechanical properties:

High strength and toughness: Excellent tensile and compressive strength, making them resistant to heavy loads and impact.

Elasticity: Retains flexibility under stress, ensuring durability in dynamic applications.

Abrasion resistance: Resists wear and tear, even in harsh conditions.

Dimensional stability: Maintains shape under varying temperatures and loads.

• Chemical resistance:

Corrosion resistance: Resists saltwater, oils, greases, and most marine chemicals.

UV stability (optional): Certain grades are UV-resistant, which is essential for prolonged outdoor exposure.

• Thermal properties:

Operating temperature range: Typically between -40°c to +80°c, with specialized grades handling more extreme conditions.

• Water resistance:

Impermeable to water, ensuring stability and durability in wet or submerged environments.

• Hardness:

Measured on the shore hardness scale (A or D), typically ranging from shore A50 to shore D80 depending on the application. Softer grades (lower shore a) offer flexibility, while harder grades (higher shore D) provide rigidity.

• Lightweight:

Despite their robustness, polyurethane boards are relatively lightweight compared to metal or similar materials.

Applications in the marine field

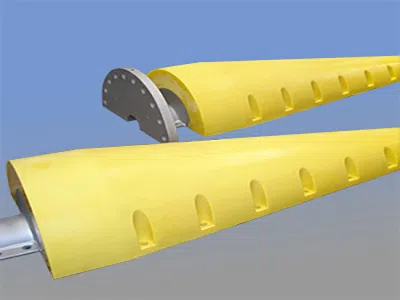

• Dock and fender systems:

Used as pads or fender components for energy absorption and protecting vessels during mooring.

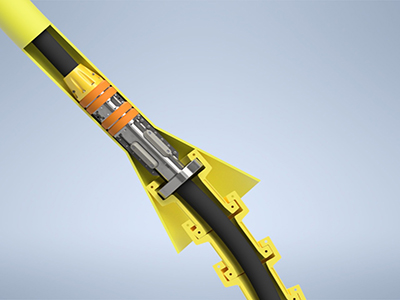

• Seals and gaskets:

Excellent sealing materials for hatches, watertight compartments, and piping systems.

• Wear pads and liners:

Utilized in high-wear areas such as sliding components, pulleys, and guides to reduce friction and extend service life.

• Buoyancy components:

Polyurethane boards with lower densities are used in floatation devices or buoyant structures due to their water resistance and lightweight nature.

• Decking and flooring:

Provides durable, slip-resistant surfaces that can withstand saltwater exposure.

• Protective coatings:

Used as base materials for protective layers or insulation in shipbuilding and offshore platforms.

Key considerations for marine use

• Select grades with appropriate hardness (shore D50–70 for structural applications; shore A60–80 for flexible uses).

• Opt for UV-stabilized variants for outdoor exposure.

• Confirm compliance with marine-specific standards such as ABSs, DNV, or lloyd's register.

Polyurethane boards are ideal for marine environments due to their strength, durability, and adaptability to challenging conditions.

Philson provides standard or customized polyurethane sheets. The hardness, material, resilience, size, etc. can be customized according to your needs. Philson has provided relevant plates to many countries. If you need it, please feel free to contact us.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.