Polyurethane-resistant safety buffer blocks are solutions specifically designed to mitigate collision damage, reduce vibration, and withstand exposure to corrosive chemicals. Ideal for heavy-duty applications, these buffers combine advanced polymer technology with precision engineering to ensure reliable performance in manufacturing, logistics, marine, and energy sectors.

Why are polyurethane-resistant safety buffer blocks so great?

In industrial environments, impact protection is essential to reduce downtime and prevent expensive damage to machinery and products. Polyurethanes offer excellent shock absorption capabilities, higher load-bearing capacity, improved tear resistance, and superior performance in extreme temperatures. They provide a robust solution for industries that require reliable and durable impact buffers. Unlike traditional rubber or plastic alternatives, polyurethane's elasticity ensures it can return to its original shape after being deformed under heavy use conditions, making it ideal for applications involving repeated impacts. In addition, polyurethane is more resistant to chemical degradation than rubber or plastic, ensuring the buffers maintain their integrity even in harsh environments.

Key benefits of polyurethane impact protection buffers

• Chemical resistance: Unlike traditional rubber buffers, they resist corrosive substances such as oils, solvents, and seawater. Can be used in temperatures from -40°c to 120°c and UV exposure.

• Superior durability: Polyurethane is known for its excellent abrasion resistance, ensuring that safety bumpers remain effective and absorb energy even under continuous impact and pressure.

• Shock absorption and impact resistance: These bumpers are specifically designed to absorb shock and impact, reducing the possibility of damage to equipment or cargo during handling or transportation. Impact forces are reduced by up to 70%, protecting equipment and extending service life.

• Extended service life: Because energy-absorbing PU blocks are highly elastic and can quickly return to their original shape after being squeezed, they can last longer than traditional materials, reducing replacement frequency and maintenance costs.

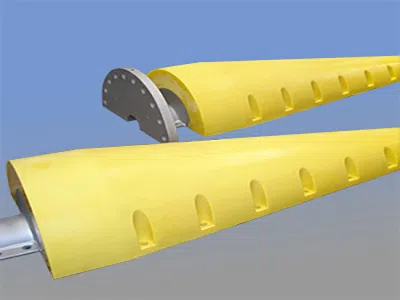

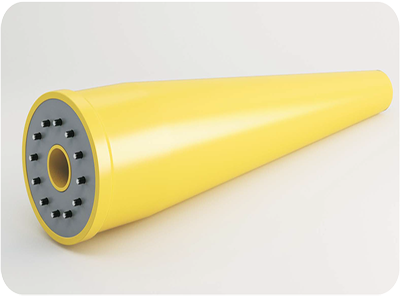

• Versatility: These bumpers are suitable for a wide range of industrial applications, from conveyor systems and heavy machinery to vehicles and storage units, and can be customized to meet specific operational needs.

• Cost-effective: By preventing damage and reducing equipment wear, these bumpers maintain structural integrity under high load capacities (compressive strength up to 500 mpa) while helping to reduce repair costs, downtime and maintenance, providing long-term value to industrial operations.

Urethane impact protection pad applications

Durable polyurethane pads are used in numerous industries and applications, including:

• Marine and ports: Used as dock fenders or ship bumpers to resist saltwater corrosion and abrasion.

• Oil and gas: Protect pipelines and drilling equipment from chemical degradation and mechanical stress.

• Material handling systems: Protect conveyor systems, lifts, and automated storage and retrieval systems from impact damage.

• Heavy machinery: Provides shock absorption for cranes, forklifts, and other heavy equipment used in construction, mining, and manufacturing.

Polyurethane bumpers are an excellent choice for industries seeking reliable and durable bumper solutions. These bumpers offer excellent shock absorption, enhanced durability, and long-term value, which are essential for protecting equipment, cargo, and personnel in high-stress environments. Whether used for material handling, heavy machinery, or logistics, polyurethane bumpers are an effective solution to minimize damage and increase operational efficiency.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.