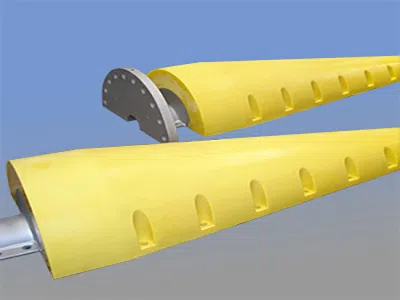

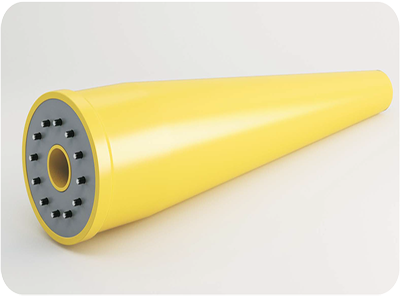

As an important accessory in modern port and shipbuilding, polyurethane flat boat fenders bumpers have gradually become an ideal buffering tool between ships and docks, floating ships, and fixed structures. Polyurethane fenders play an indispensable role in busy ports, ship loading and unloading operations, or berthing operations on offshore platforms. Due to their excellent performance, polyurethane fenders are replacing traditional rubber fenders and becoming a more advantageous choice.

Features of polyurethane fenders

• Excellent energy absorption capacity

One of the biggest features of polyurethane fenders is their excellent energy absorption capacity. Polyurethane materials have higher elasticity and compression resistance. When a ship is berthing or colliding, polyurethane fenders can quickly unload force and automatically rebound, which can effectively prevent the hull from being over-impacted, protect the safety of ships and docks, and reduce maintenance costs.

• Long-lasting durability and reduced maintenance costs

The special formula of polyurethane anti-collision blocks is naturally immune to seawater corrosion in the harbor environment ravaged by salt spray, oil pollution, and ultraviolet rays, eliminating the need for painting and maintenance of steel fenders. Ordinary materials may "retire" in 3 years, but polyurethane fenders can last for more than 15 years. The wear-resistant surface hardness does not fall off even after repeated friction. Polyurethane fenders have strong weather resistance and long service life, which can significantly reduce the frequency of maintenance and replacement, saving a lot of money for ports and ship operators.

• Good environmental adaptability

Polyurethane buffers have excellent environmental adaptability. Whether it is extreme low temperature, hot and humid tropical environment, or salt spray erosion offshore environment, polyurethane fenders can maintain excellent energy absorption performance. Polyurethane anti-collision blocks can not only withstand environments with large temperature differences, but also withstand seawater erosion without corrosion or decay. Polyurethane fenders are more stable and more adaptable in marine environments.

• Lightweight and easy to install

Polyurethane fenders are lighter and easier to install than traditional materials. Polyurethane materials have a lower density. Under the same size, a single polyurethane fender is lighter (70% lighter than the same specification steel), which is more labor-saving to install, reducing installation time and labor costs. In addition, the structural design of polyurethane fenders is more flexible and can be customized according to different needs to adapt to various docks and ship types.

• Environmentally friendly and noiseless

Compared with traditional rubber, polyurethane materials have more friendly ecological performance. The polyurethane fender system is made of harmless materials, does not pollute the ocean, can be recycled and reused after the service life, and meets modern environmental protection requirements. It is an ideal choice for ports, ships and other fields. Polyurethane fenders absorb noise, and the special structure reduces the collision sound by 30%, protecting the hearing of crew members. The anti-fouling surface that imitates the texture of shark skin makes it "nowhere to settle" for organisms such as barnacles

Application areas of polyurethane fenders

• Ports and docks

• Ships

• Floating platforms and offshore facilities

• Fisheries and other marine transportation

Polyurethane fenders have become important equipment for modern ports and ships with their excellent energy absorption capacity, durability, environmental adaptability and environmental protection characteristics. It is widely used in ports, ships and offshore platforms, significantly improving safety and reducing maintenance costs. Polyurethane fenders have promoted the development of the marine industry in a more efficient and sustainable direction, and are a key technology to ensure the safety and efficiency of marine operations.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.