Deepwater polyurethane foam buoyancy is commonly used in floating production systems where flexible risers, cables, and umbilicals are fixed to the seafloor using specific geometric structures to prevent damage during operation. A widely used method involves installing distributed buoyancy modules on the outer surface of the pipeline. To ensure long-term stability, the buoyancy load must remain consistent and not decrease throughout the product's design life.

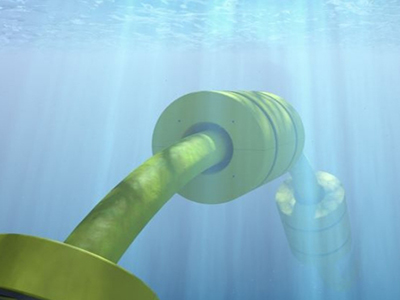

Function and installation of buoyancy modules

Distributed buoyancy modules are primarily used to connect subsea facilities to vessels or platforms on the water's surface. By implementing a clamping solution, the buoyancy module can be installed at any required position along the pipeline. The core functions of the buoyancy module are twofold: firstly, to provide sufficient lift, and secondly, to maintain the pipeline’s stable position along the riser. The lift is generated by two separate buoyancy components, and the clamp holds the buoyancy assembly securely at the required position. Once the buoyancy section is assembled, it is mechanically locked in place around the clamp and reinforced with an annular band.

Adaptability of deepwater buoyancy systems

To meet specific project requirements, the buoyancy system can be adjusted to ensure efficient operation in waters up to 6,000 meters or even deeper. Supported by large floating buoyancy modules, suspended pipelines can float in waters as deep as 250 meters without being affected by water pressure. These systems also do not interfere with shipping activities. An efficient buoyancy solution is crucial for maintaining pipeline performance and ensuring safety during deployment.

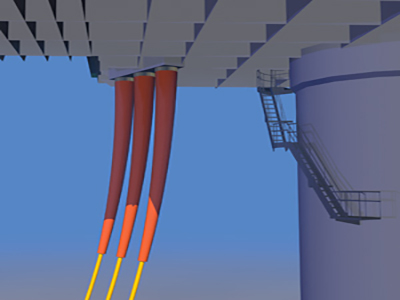

Buoyancy modules in dynamic applications

In dynamic applications, such as offshore floating production facilities or terminals, flexible pipelines, and umbilicals require buoyancy modules to reduce top tension loads. These modules help the pipelines achieve special configurations like steep, lazy, W-wave, and flexible forms. These dynamic applications typically involve connections to other floating facilities or fixed structures, and buoyancy modules play a critical role in their stability and functionality.

Design and advantages of Philson buoyancy modules

Philson's subsea distributed buoyancy modules feature an internal clamping system combined with synthetic foam buoyancy elements. The buoyancy element is divided into two halves, and the internal grooves are designed to transfer the buoyancy force to the clamp and subsequently to the flexible pipeline. This design allows the modules to adapt to the pipeline’s bends during deployment and maintenance, while also being optimized for deepwater applications. These buoyancy modules are capable of operating in water depths exceeding 3,000 meters with stable performance.

Fast installation and customized solutions

Philson’s buoyancy modules and installation tools are designed to reduce installation time significantly. After correct deployment, the installation process can be completed in as little as six minutes, dramatically cutting down on ship operation costs. The density and composition of these modules can be customized to meet specific project needs, including hydrostatic pressure, buoyancy requirements, water inflow conditions, pipe diameter, and length.

Buoyancy systems for extreme environments

For projects involving high-temperature operating conditions, Philson’s buoyancy modules utilize specially formulated polyurethane foam components that are designed to withstand high environmental and pipe temperatures. This ensures that the buoyancy modules continue to operate effectively under extreme conditions. The outer coatings of these modules are finely processed to provide superior wear resistance, impact resistance, and protection against marine biofouling, ensuring reliable performance in challenging subsea environments.

Standardized modular buoyancy solutions

In response to customer feedback, Philson has developed a range of modular buoyancy products aimed at maximizing buoyancy while maintaining a unified design philosophy. Using a standardized clamping system, Philson offers incremental buoyancy modules made from polyurethane foam systems, suitable for deepwater applications ranging from 0 to 3000 meters. These pre-engineered solutions are cost-effective and ensure high-quality buoyancy support, even within tight project timelines and budget constraints.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.