No.19 Industry Park, Dongtai, Jiangsu, China WhatsAPP: +86 19941574798 sale01@kfzhgc.com

No.19 Industry Park, Dongtai, Jiangsu, China WhatsAPP: +86 19941574798 sale01@kfzhgc.com

Philson Intelligent Equipment (Jiangsu) Co., Ltd., based in Jiangsu, China, is a specialized manufacturer for the global offshore energy sectors. We specialize in high-performance protection and stability systems for cable and pipeline protection, such as bend restrictors, bend stiffener and centralisers. With a strong service network across Europe, Asia, North America, and the Middle East, our technologies are vital to offshore oil & gas, offshore wind energy, and marine engineering. We are dedicated to providing the technical expertise and reliability necessary to advance global marine resource development.

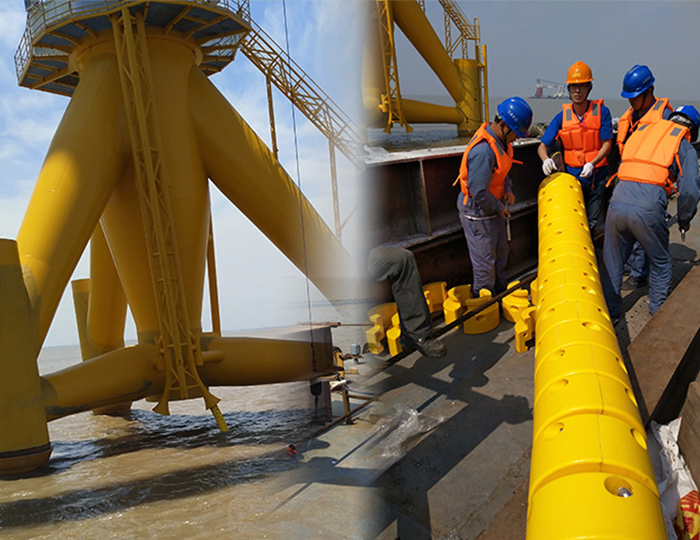

Our Bend Restrictors are specifically engineered to protect cables, umbilicals, and hoses during installation and operation. We primarily serve the following sectors:1. Offshore Wind: Protecting inter-array and export cables at the interface with foundations (monopiles, jackets) and J-tubes.2. Oil & Gas: Ensuring the structural integrity of flexible risers, umbilicals, and subsea jumpers in harsh deepwater environments.3. Oceanographic Research: Safeguarding power and data connections for subsea sensors and monitoring equipment. 4. Marine Telecommunications: Providing robust protection for fiber optic cables at shore landings or near offshore platforms.

Our products are designed to provide absolute reliability in extreme subsea conditions through:1. Interlocking Design: A precision-engineered modular system that mechanically limits the bending radius, ensuring it never falls below the manufacturer's Minimum Bend Radius (MBR).2. High-Performance Polymers: Manufactured from high-grade Polyurethane (PU), offering exceptional creep resistance, seawater corrosion resistance, and a design life of over 25 years.3. Ease of Installation: The split-unit design allows for rapid assembly on deck or subsea without specialized tools, maximizing efficiency during tight offshore weather windows.4. Fatigue Resistance: Rigorously tested to withstand cyclic loading from ocean currents and wave motion, preventing long-term material degradation.

Yes, we provide fully bespoke solutions tailored to your specific project requirements. Since every subsea project has unique parameters, we offer:1. Dimensional Customization: Tailoring internal diameters and overall lengths based on your cable's outer diameter (OD) and operational water depth.2. Performance Simulation: We can provide data support to assist with dynamic analysis (such as Orcaflex) to recommend the optimal configuration for your site conditions.3. Project-Specific Branding: Custom colors (e.g., high-visibility Safety Orange or Yellow) and molded-in project IDs or company logos.4. Material Optimization: Adjusting polymer formulations for specific environments, such as arctic cold or ultra-deepwater high-pressure conditions.

The performances of bending restrictors are evaluated based on several key parameters: bending limitation, load bearing capacity, durability and fatigue resistance, material properties, installation compatibility, adaptability to environmental conditions and flexibility.

Offshore bend restrictors are critical for subsea wind cable integrity. By enforcing Minimum Bend Radius (MBR), they prevent sheath micro-cracks and seawater ingress, effectively neutralizing galvanic corrosion.

Philson 12 Jan 2026Compare Bend Stiffeners vs. Bend Restrictors (VBR) for subsea engineering. Learn about MBR management, VIV suppression, and why dynamic zones require tapered stiffeners.

Philson 29 Dec 2025Solve subsea cable over-bending with our heavy-duty polyurethane bend limiter. Modular design allows easy installation and length adjustment, drastically reducing maintenance costs for offshore energy projects.

Philson 10 Dec 2025Cable protection marine bending limiters, engineered to shield subsea and offshore cables from damage caused by excessive bending, buckling, and mechanical stress.

Philson 24 Nov 2025